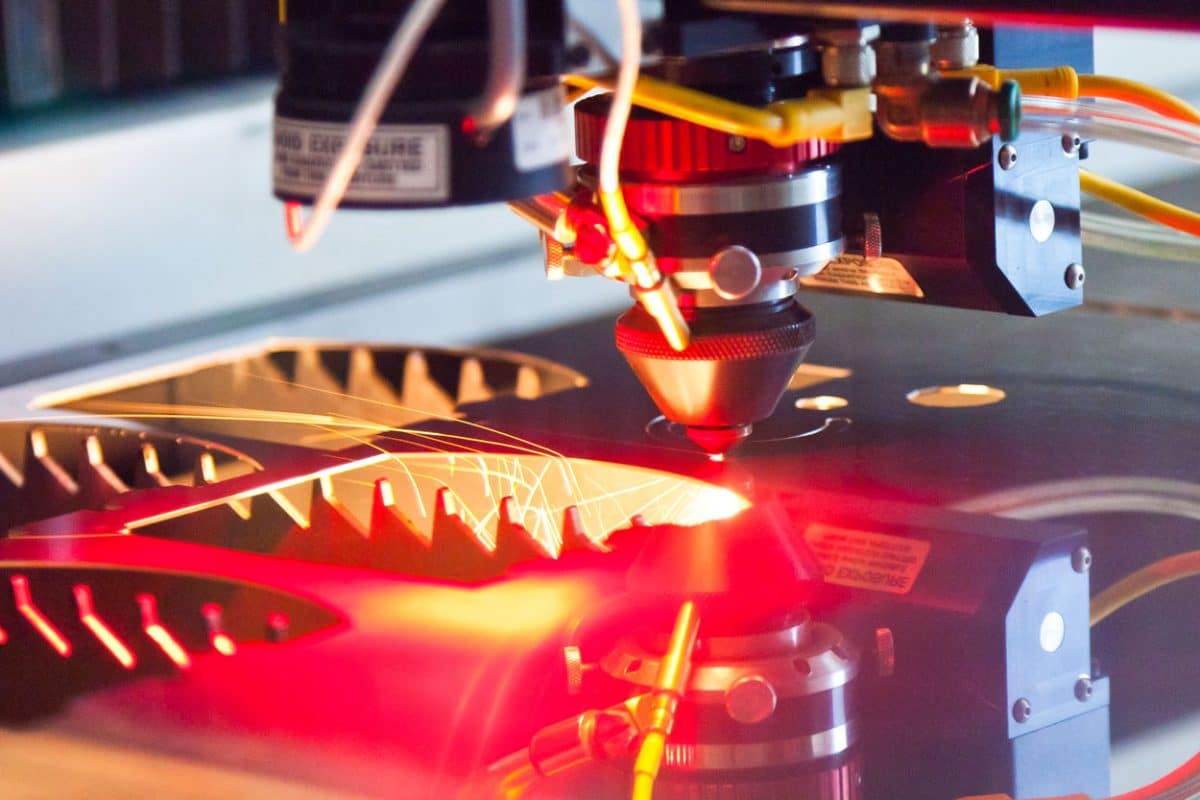

Laser Cutting

Hollinbrow is the Experts in Thin Metals. One of our specialities is the laser cutting of metals from 0.010mm to 3.00mm thick. We are not a job shop that needs to cut the parts as quickly as possible, taking no care of the quality of the parts they are producing. Hollinbrow ensures that the parts they produce are of the highest quality. No pips, no edge burrs, no dross and no splatter, just a quality part you will be proud of.

Send us your drawing and the tolerance’s you require, and we will do the rest. Go to our contact page to make an enquiry about the tolerances you need.

We laser cut from 0.010mm thick in stainless steel, mild steel, carbon steel, brass, phosphor bronze, aluminium and nickel alloys.

Laser-cut parts can be supplied in quantities as small as one off’s.

Laser cutting is a technology that uses a laser to slice materials. While typically used for industrial manufacturing applications, it is beginning to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns vaporize away, or is blown away by a jet of gas,[1] leaving an edge with a high-quality surface finish.